Wednesday, September 9, 2009

The Way of Strategy (10): A Tangible Strategy!

Building and implementing a strategy under a chaotic setting is solitary, poor, nasty, brutish and rarely ever short enough.

- paraphrased from Thomas Hobbes

It is always a challenge to build a strategy that can be adjusted to the parameters of an uncertain setting, with the specific guidelines focused on being efficient.

Our Compass rule for operating under tentative settings is to maintain a few guidelines that enables one to be flexible while focusing on building a predictable and efficient setting by using metrics and detailed analysis processes.

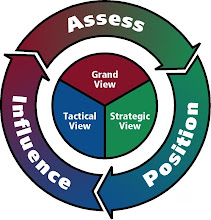

In competition, a good strategy is built on the theory of establishing order while creating disorder within their competitor settings. It begins by assessing the grand situation and then the different micro situations that comes with it.

Our strategic assessment process begins by identifying the variables that are in play. Then determine a list of general and specific tangible measures that comes with it. The next step is evaluate the tangible risks for each variable.

The quantity of quality information and the professional experience of the strategist usually determines the quality of strategic assessment and planning.

Through the assessment process, one can develop standards that can be used for maintaining performance and quality. "A strategy without tangible measures is a strategy that borders in the realm of illusions."

#

Welcoming the New, Improving the Old

By SARA BECKMAN

FOR decades, companies from Cisco Systems to Staples to Bank of America have worked to embed the basic techniques of Six Sigma, the business approach that relies on measurement and analysis to make operations as efficient as possible.

More recently, in the last 5 to 10 years, they have been told they must master a new set of skills known as “design thinking.” Aiming to help companies innovate, design thinking starts with an intense focus on understanding real problems customers face in their day-to-day lives — often using techniques derived from ethnographers — and then entertains a range of possible solutions.

To many, the two skill sets don’t fit together well, and Chuck Jones, vice president for global consumer design at Whirlpool, explains why that may be so. Design thinkers, he says, are like quantum physicists, able to consider a world in which anything — like traveling at the speed of light — is theoretically possible. But a majority of people, including the Six Sigma advocates in most corporations, think more like Newtonian physicists — focused on measurement along three well-defined dimensions.

Six Sigma, a kit of analytical tools first developed in the 1980s at Motorola, has been embraced by many businesses — big and small. Joy Ulickey, a quality consultant in San Francisco, applied them in 2008 to help a midsize Sonoma winery figure out why it was having so many failed fermentations.

Through a detailed analysis of possible factors affecting fermentation, like yeast type, temperature and the rate of cycling wine through the tanks, Ms. Ulickey identified the primary problem as temperature control. Then she suggested several “countermeasures,” including hiring workers to monitor temperature or investing in newer fermentation tanks. Her work allowed the winery to save hundreds of thousands of dollars a year and improve its wine.

On a much larger scale, it is unimaginable that Intel could produce a single one of its highly complex semiconductor chips or that Procter & Gamble could deliver laundry detergent of consistent quality globally without these types of analytical techniques.

Design thinking can be equally effective, but in different ways. While in business school, Jeff Denby and Jason Kibbey concocted an online underwear company called Pact, applying design thinking to understand prospective customers and to rethink how underwear is developed and sold. They visited underwear stores and asked friends and family to send pictures of the underwear in their dresser drawers, or, for those brave enough, shots of themselves posing in their favorite boxers or panties.

They tested different approaches to marketing, including subscription programs, and different ways of developing stylish products. For example, they considered letting up-and-coming designers compete to create designs showcasing particular causes.

Today, their company, based in Berkeley, Calif., sells organic cotton underwear created by the designer Yves Béhar. The designs use graphics that highlight the work of groups like 826 National, which helps young writers, and a portion of revenue is contributed to those causes.

To survive, many businesses will have to figure out how to incorporate both approaches. Design thinking offers tools for exploring new markets and opportunities; Six Sigma skills can be applied to improve existing products. Companies that adhere strictly to one or the other risk failure. “The practices that make for success at one time can trap firms and contribute to their downfall at a later time,” says Bob Cole, a quality expert and professor emeritus at the Haas School of Business at the University of California, Berkeley.

Professor Cole uses the history of the Japanese DRAM industry to illustrate his point:

In the early 1990s, Japanese DRAM producers doggedly pursued quality improvement, investing in engineering and equipment to develop products of higher and higher quality. The market, however, was shifting from mainframes to personal computers, a shift that South Korean producers observed.

Samsung, for example, released a 128-megabyte DRAM in 2000 that was a perfect fit for vendors of low-priced PCs, and it leveraged that design into other products. By gathering valuable knowledge on emerging user needs, Samsung was able to rapidly respond to a changing market, while Japanese producers slowly left the DRAM field.

According to Michael Barry, a consulting assistant professor at the Hasso Plattner Institute of Design at Stanford and a partner at the design firm Point Forward, the Six Sigma process starts with an assumption about what is good — like higher-quality DRAM chips. Design thinking, meanwhile, inquires as to what is good — as lower-cost, higher-speed DRAM chips were for PCs and other products.

THE different world views, however, can be brought together.

At Whirlpool, Mr. Jones first proved the value of design with the introduction of the Duet washer and dryer. Duet’s novel, easy-to-use, energy-efficient design made Whirlpool a player in the front-loader market. After that success, he invited Whirlpool’s Six Sigma experts to help him improve design processes. They developed various new metrics — for how customers evaluate product quality, for example — that allowed designers and Six Sigma types to understand each other better.

Progressive Insurance has also turned design and Six Sigma techniques into reasonably comfortable bedfellows. In the early 1990s, it started emphasizing showing up at an accident scene and handling situations in real time, according to a 2004 article by Michael Hammer in The Harvard Business Review. That move reflected a designer’s way of thinking about customer needs, but the company was able to execute the idea through its ability to measure, analyze and improve its processes.

Both worlds — the quantum one where designers push boundaries to surprise and delight, and the Newtonian one where workers meet deadlines and margins — are meaningful. The most successful companies will learn to build bridges between them and leverage them both.

Sara Beckman is faculty director of the Management of Technology Program at the Haas School of Business at the University of California, Berkeley.

http://www.nytimes.com/2009/09/06/business/06proto.html?em

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment