Following is a list of why Honda dominates in the automotive industry:

Following is a list of why Honda dominates in the automotive industry:

1. Everyone in their "assembly" team can do everyone's else job.

2. Honda has a technological system that adapts to any car model.

3. Honda spends a great deal of time on the ground.

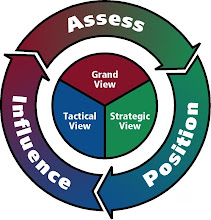

/// They always knowing what are the current and future intents of the vendors. Honda's intelligence gathering and strategic assessments protocols enable their implementers to strategize ahead.

4. They adjust strategically as a team.

/// Honda has a strategic project management process that enables the team to collaborate anywhere as a team, Regardless of the times, Honda has a grand strategic process (a Tangible Vision) that enables them to adjust strategically. Currently, they are #1 in car manufacturing in the United States.

#

July 3, 2008 The Struggles of Detroit Ensnare Its Workers

By BILL VLASIC and NICK BUNKLEY

DETROIT Their pickups and sport utility vehicles are not selling, and now General Motors, Ford Motor and Chrysler have to pay thousands of auto workers not to make them.

With more than 15 of their assembly plants across the country set to be idled or slowed because of shift cutbacks, the Detroit automakers will temporarily lay off upward of 25,000 auto workers this summer and fall.

Because of their union contracts, G.M., Ford and Chrysler are obligated to pay workers more than half of their regular take-home wages, plus health benefits, with state unemployment benefits picking up a portion of the rest.

Despite cutting more than 100,000 jobs since 2006 through buyouts and special retirement programs, the Detroit companies still cannot match their production capacity with their steadily declining market share.

Consumers are shifting to more fuel-efficient vehicles, if they are stepping into a showroom at all. New vehicle sales plummeted 18 percent in June, and Detroit's share of the declining market fell to a combined 46 percent.

Moreover, all three companies are losing money in North America and burning through cash reserves. On Wednesday, G.M.'s stock fell 15 percent after a Merrill Lynch analyst issued a report saying that "bankruptcy is not impossible" if the overall market continues to deteriorate.

Unlike many factories operated by Japanese manufacturers in the United States, Detroit's plants are not flexible enough to switch their production to better-selling models.

So while some G.M. and Ford factories are scrambling to build more cars, even paying workers overtime to meet demand, other assembly lines are shutting down.

"It's an unprecedented situation," said Harley Shaiken, a labor professor at the University of California, Berkeley. "Despite enormous reductions in total employment, the market is forcing massive temporary layoffs."

Detroit's Big Three, it appears, can't escape their past.

Since the 1980s, the companies by dint of their contracts with the United Automobile Workers union have parked idled workers in so-called "jobs banks" where they received full pay while doing community service or simply clocking in.

New contracts with the U.A.W. signed last year were supposed to pave the way for elimination of the jobs banks and make the companies more competitive on health care and wages for new hires.

In addition, the historic buyout and early-retirement programs were meant to better align, at enormous expense, the automakers' workforce with demand for its vehicles. Even before this year, the companies had announced plans to close several plants.

But the restructuring plans did not account for the huge drop in sales and the shift by consumers to smaller vehicles that have resulted from soaring gas prices and the weak economy.

"You have the demand for large vehicles dropping, combined with growing demand but limited supply of smaller vehicles," said Jesse Toprak, executive director of industry analysis for Edmunds.com, an automotive-research Web site. "What you end up with is miserable sales numbers."

Rather than flood the market with unwanted trucks and S.U.V.'s, the Detroit automakers have announced broad, temporary layoffs on a scale unseen since the early 1990s.

"Instead of building vehicles and selling them at deep discounts, the companies are shutting the plants," said Ron Harbour, managing partner of the consulting firm Oliver Wyman, which issues a widely followed annual report on auto manufacturing trends. "It's painful, but it's smarter than the alternative."

G.M. plans to send about 11,000 United States workers home on layoffs the rest of the year, some for weeks and others for months. It also has about 1,000 workers still on the rolls of jobs banks from plants long since closed.

Ford is idling about 5,000 of its hourly employees, in addition to the estimated 500 workers it has in the jobs bank. Chrysler, which has 300 people in the jobs bank, will lay off about 9,500 workers.

There are also layoffs scheduled at plants in Canada and Mexico.

Virtually all of the laid-off workers are at plants building slow-selling pickups like the Ford F-Series or big S.U.V.'s such as G.M.'s Chevrolet Suburban and Chrysler's Dodge Durango.

Some of those workers will, over time, be moved to car plants that are adding shifts or otherwise increasing production.

But the vast majority of the laid-off workers in the United States will stay at home and collect 95 percent of their average after-tax, take-home pay about $816 a week, according to U.A.W. documents posted on the union's Website.

Of that $816, the automaker pays about 55 percent and state unemployment covers the remainder. In G.M.'s case, the cost of supporting 11,000 laid-off workers averages about $1 million a day.

"It is a very expensive issue, but it's not the critical one for Detroit," said Mr. Shaiken. "The reason these plants are going down is that some catastrophic decisions were made in the past to continue building so many trucks."

The companies are trying to mitigate the impact of the production changes. Ford, for example, will cut a shift at its Missouri truck plant and almost immediately move the workers to a nearby factory making small S.U.V.'s.

At a Kentucky plant that makes Explorer sport utility vehicles, Ford will slash production from two shifts to one. But rather than lay off workers, the shifts will start to alternate work weeks.

Still, the Detroit automakers are hamstrung by the inability of their factories to shift production from slow-selling vehicles to hotter models. Rivals such as Honda can quickly move from making an S.U.V. such as the Element in its Ohio plant to Civic sedans.

"The key is they are able to change the mix of products to what is selling right now," said Mr. Harbour.

While plants operated by G.M., Ford and Chrysler have markedly improved their productivity and lowered their worker rolls in recent years, they generally are confined to making variations on a single truck or car platform.

The stunning drop in truck sales has forced the Detroit companies to make some hard decisions. Chrysler this week said it will close a minivan plant in Fenton, Mo., near St. Louis, and cut a shift at a neighboring factory that makes Ram pickups.

The double blow stunned workers. About 1,500 workers at the minivan plant will go on indefinite layoff in October, while 900 workers at the Ram factory will be idled in September.

"It's very scary," said Joe Wilson, a 40-year-old worker at the minivan plant. "We'd been led to believe we'd have a future. Now they pull the rug out from under us."

Mr. Wilson said that getting a paycheck for not working is hardly a relief when his job is disappearing. He was already cutting back on expenses, and had bought an old Ford Escort to save money on gas for his commute.

"It takes three weeks to get that first check and by then we owe everybody and their uncle," he said.

A worker at the Ram pickup plant, Dave Jacobs, said the plant's long-term prospects have been clouded by the reduction to one shift.

"They can't afford to run this place with one shift," he said. "One shift pays the bills and the others are for profits."

Laid-off workers can receive their unemployment pay for up to 48 weeks. At that time, workers can shift into the jobs bank for another two years.

But one Chrysler worker, Andy Marlow, said the cutbacks are coming so fast that employees fear the worst.

"You can sit and try to ride it out and hope the plant comes back up," said Mr. Marlow. "But then if that pay runs out, you're unemployed."

Bill Vlasic reported from Detroit, and Nick Bunkley from Fenton, Mo.

http://www.nytimes.com/2008/07/03/business/03auto.html

--- eof

If your company needs a strategic collaborative management process that enables your team to collaborate anywhere as a team regardless of the distance, the technology and the project culture.

Please contact us at service [aatt] collaboration360 [dottt] com. We have a white paper ready for your reading.

.jpg)